PACK Expo (PMMI Show) Was Virtual But 2 To 18 Lane Stick Pack & Checkweighers Are Still Live!

/0 Comments/in Blog, Press Release, Trade Shows/by Ralph FrenchSince we missed you at Pack Expo this year, here is a virtual show of how we can meet your packaging production needs. Stick Pack machines ranging from 2 lane to 18 lane with 80 to 720 sticks per minute throughput. Each being accurately checked by the automated checkweigher with feedback to the filler. Give us a call 866-FASTech (866-327-3324) to find out more.

https://packexpo19.mapyourshow.com/8_0/exhibitor/exhibitor-details.cfm?exhid=02022459

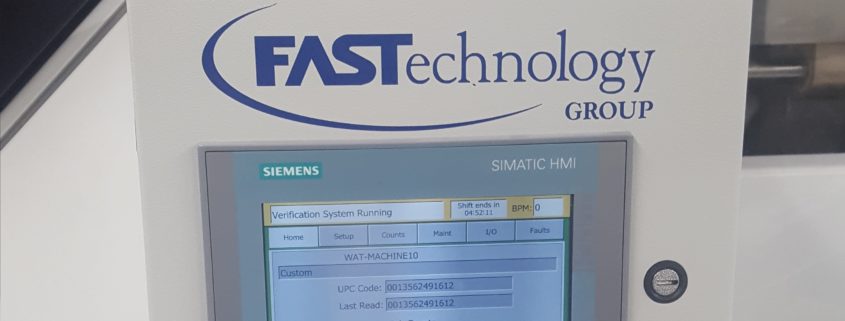

See FASTech’s UPC Verification System Case Study in Control Engineering Magazine

/0 Comments/in Blog, Press Release/by Ralph French

FASTechnology Group adds UPC Verification to Flexible Packaging (Bagging) Machines in Packaging Industry

Challenge: Supplement existing machines with an efficient, robust system to verify the correct pre-printed packaging is used for the product being packaged, 100% of the time.

Solution: Using the latest in PLC controls, HMI, and machine vision technology, as well as custom software and database development, FASTechnology Group created a system to read, compare and verify the UPC barcode of each and every product made against the plant’s ERP system.

Result: A system that integrates seamlessly with the existing production lines, monitoring the necessary aspects to improve line consistency and make mismatching of product to packaging a thing of the past.

Summary: In the Consumer Packaged Goods industry, a simple mismatch of pre-printed package to product can quickly spiral into a safety concern for consumers, not to mention countless dollars lost on wasted products, recalls, and downtime. For example, a packaging line cannot have peanuts going into a potato chip bag. The risks of only checking the spool of film prior to running the line doesn’t always cut it. When FASTechnology Group was tasked with modifying existing production lines to verify the UPC of each and every bag, the company was able to use the latest in industrial controls across a wide array of technologies to deliver a solution to the customer.

The system combines an industrial logic controller, a machine vision barcode reader, and custom server-side software to cross-reference the physical UPC with the one in the Plant Management Software. As one of FASTech’s customers states: “Using this system, we are able to limit the pulling of jobs down from the plant management system to only those scheduled for the current shift. This keeps the user interface out on the plant floor clean, simple to use, and efficient.”

Here is a link to the original Case Study…

The importance of knowing what your OEE is!

/3 Comments/in Blog, Industry News/by adminOverall Equipment Effectiveness (OEE) Part 4 of 4 Part Blog

Now that you know how to calculate OEE, what do you do with it? How is it useful? What is a good number?

Knowing your OEE helps you understand your manufacturing health, know when to take on additional orders, when to make new equipment acquisitions, and when not to.

Once you have started the daily process of calculating and tracking your Overall Equipment Effectiveness, addressing manufacturing problems early becomes straightforward. Being able to break your OEE calculation back down to its three basic components, Availability, Productivity, and Quality, tells you exactly where the problem is.

When it comes to taking on additional orders, knowing your OEE is critical. If you have an OEE of 85% or higher, congratulations, unfortunately you are most likely at the capacity of your equipment. Knowing your OEE in this case should help you justify new equipment and calculate its ROI. Now, if your OEE is low, that’s not necessarily a bad thing, if a low Availability number is the cause. If Productivity or Quality are the cause of your low OEE, then maybe unreliable or worn-out equipment should be replaced.

What is a good OEE? The common thought is that world-class OEE is anything above 85%. If you have an OEE of 85% that is fantastic, congratulations are in order. Keep in mind you still have a 15% loss. The benchmark of 85% is just that, a benchmark. Good OEE is up to the manufacturing facility to determine for itself.

At FASTechnology Group we understand what it takes to get good product out, efficiently. Together we can erase benchmarks, establishing new ones. Let our +30 years of packaging experience help you improve your OEE

Here is a Link to Part One “What is OEE and How Can It Be measured?”

How Proper Operator Training and Maintenance Improve OEE

/0 Comments/in Blog, Industry News/by adminOverall Equipment Effectiveness (OEE) Part 3 of 4 Part Blog

Now that we understand what OEE is and the contributing factors to its loss; how does operator training and maintenance really improve your numbers? Again, we look to the equation, OEE = Availability x Productivity x Quality, then break it down from there.

AVAILABILITY, A correctly trained maintenance team will be able to conduct repairs and perform preventative maintenance in a timely and efficient manner. As packaging equipment machines speeds increase the complexity of the technology required to control these machines increases as well. Twenty years ago a typical packaging machine consisted of a couple motors, a small microcontroller, maybe a touch screen, and some other miscellaneous hardware. Today’s machines have multiple servo motors, advanced PLCs, and complex safety circuits, so training becomes more and more critical when troubleshooting. An untrained or poorly trained maintenance team will struggle to make repairs, in some cases further damaging the machine. With the correct training you can prevent a costly emergency repair call from an outside service provider. When a machine operator has received the proper training he or she will run the machine as designed avoiding practices that are hard on the equipment, eventually causing downtime.

PRODUCTIVITY, Correctly trained operators have an increased confidence in their ability to operate packaging equipment machines smoothly, this contributes to a more positive attitude. Without training operators struggle, get frustrated, waste film and product, damage equipment, causing a lower output than trained operators. Trained operators make operating a machine look easy, they are not tied to the machine, allowing them to perform other tasks as the machine runs.

QUALITY, Trained maintenance staff and operators know exactly where to look on a machine when they discover a quality issue with a package. The result of the confidence and positive attitude that training provides is shown in the pride a skilled operator takes producing the best package possible.

Let FASTechnology’s packaging experts help you discover what your machines are truly capable of producing. Our +30 years of packaging knowledge will increase your output, bolster your quality, and give your staff confidence that they can handle any issue on their own.

In part four of this Blog we discuss “The importance of knowing what your OEE is.”

Here is a Link to Part One “What is OEE and How Can It Be measured?”